TCB30 Bimetal Bushing

Structure Characteristics and Applications

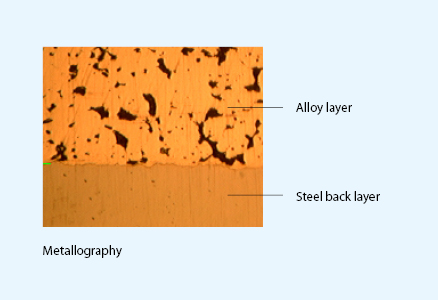

TCB301 bimetal bushing is backed with high quality low carbon steel with tin-lead-bronze alloy(CuSn10Pb10) sintered on its surface. To effectively decrease abrasion, its alloy surface can be machined with ball shaped oil sockets for easier oil storage. When necessary, it could be plated copper or tin on the steel back. It can be applied to conditions of mediate load with mediate or high running belocity and conditions with enormous impact load. In mechanical applications, TCB301 is used to make wrapped bushes, thrust washer and bushes on connecting rod level of gas engine.

Physical and Mechanical Performance

Physical and Mechanical Performance

| Performance Index | Data | |

| Max Load P | 140N/mm? | |

| Linear Velocity V | Grease Lubrication | 2.5m/s |

| Oil Lubrication | 5m/s | |

| Max PV value | Grease Lubrication | 2.8N/mm? ·m/s |

| Oil Lubrication | 20N/mm? ·m/s | |

| Alloy Hardness | HB 60~90 | |

| Mating Axis | Hardness | ≥53HRC |

| Roughness | Ra=0.16~0.63 | |

| Working Temperature | Grease Lubrication | 150℃ |

| Oil Lubrication | 250℃ | |

| Friction Coefficient | 0.05~0.15 | |

| Heat-conducting Coefficient | 47W/(m·k) | |

| Heat-expansion Coefficient(Axial) | 18×10-6/K | |

Physical and Mechanical Performance

Physical and Mechanical Performance

Strong anti-fatigue, and good load and impact bushing with good erosion protection performance. When mating with quenched hard axis, the hardness of the axis must not be less than 53HRC.Main Factors that Influence the Service life of the Bushing

Main Factors that Influence the Service life of the Bushing

1).PV ValuePV value is an effective criterion to calculate the service life of TCB301. If there is need to prolong the service Life, PV value must be reduced.

2).Environment Temperature

The higher the working temperature is, the shorter the life of the products would be.

3).Roughness

If Roughness of the mating surface Ra>0.63, it will rapidly shorten the service life of the TCB301. Therefore, Roughness of the mating surface must be controlled to Ra≤0.63.

Alloy Chemical Compositions

Alloy Chemical Compositions

| Content % | Cu | Pb | Sn | Zn | P | Fe | Ni | Sb | Others |

| Rest | 9~11 | 9~11 | 0.5 | 0.1 | 0.7 | 0.5 | 0.2 | 0.5 |

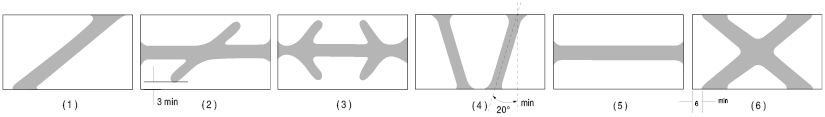

Oil Groove Types

Oil Groove Types

TCB30 Classification

-

TCB 300

Its material structure is Steel + CuPb10Sn10 + Graphite. The alloy surface is rolled to diamond oil grooves. The special lubricant is embedded in the grooves. It has good lubricating and corrosion resistance property. It can work in the condition of little of oil or none ...

-

TCB 301

Its material structure is Steel + CuPb10Sn10. It has high fatigue strength, load capacity and impact strength. The product is applied to con-rod of automobile engines, engineering and agriculture machinery, heavy duty construction machinery, etc.

-

TCB 302

Its material structure is Steel + CuPb24Sn4. It has highly fatigue strength, load capacity, impact strength and corrosion-resistance. It is widely applied to high speed, heavy load engine main shaft and transmission gearbox, etc.

-

TCB 303

Its material structure is Steel + CuPb24Sn4. It has high fatigue strength, load capacity, excellent surface property. It is mainly applied to main shaft and con rod shaft of internal combustion engine.

-

TCB 304

Its material structure is Steel + AlSn20Cu. It has medium fatigue strength, load capacity, good corrosion-resistance and super surface property. It is mainly applied to main shaft and con rod shaft of internal combustion engine, pressure-squeeze machine and ...

-

TCB 305

Its material structure is Steel + CuPb30. It has medium fatigue strength, load capacity, excellent surface property. It is mainly applied to main shaft and con rod shaft of internal combustion engine.

Product Classification

TCB10 Self-Lubricating Multilayer Composite Bushing TCB20 Boundary Lubricating Bushings TCB30 Bimetal Bushing TCB40 Oil Sintered Bearing TCB50 Solid Lubricating Bearing TCB60 Steel Bearings TCB70 Spherical plain bearing TCB80 Casting Bronze Bearing TCB90 Wrapped Bronze Bearing TCB-21 Filament Wound High Load Self-lubricating Bearings